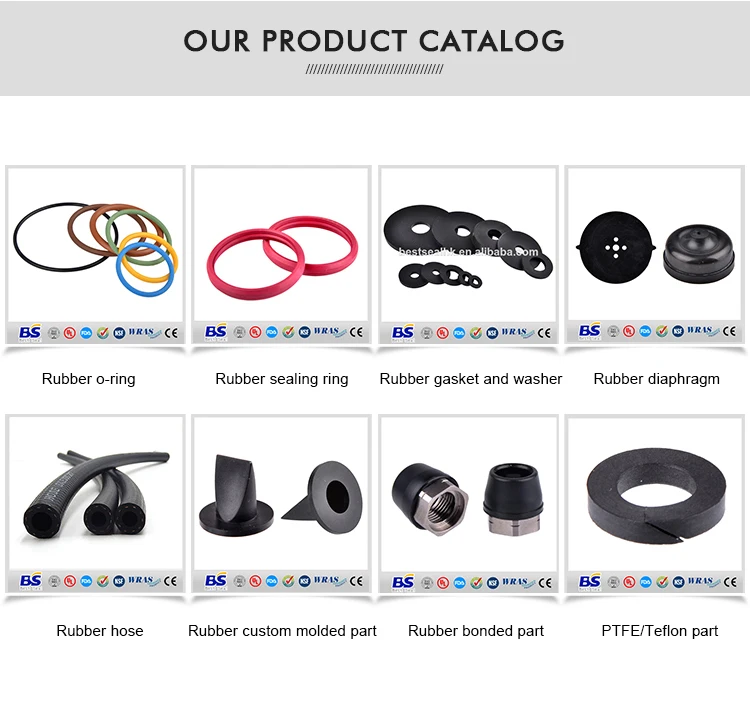

Products

- Home

- Rubber Molded Part

- Conductive electric silicone rubber seal

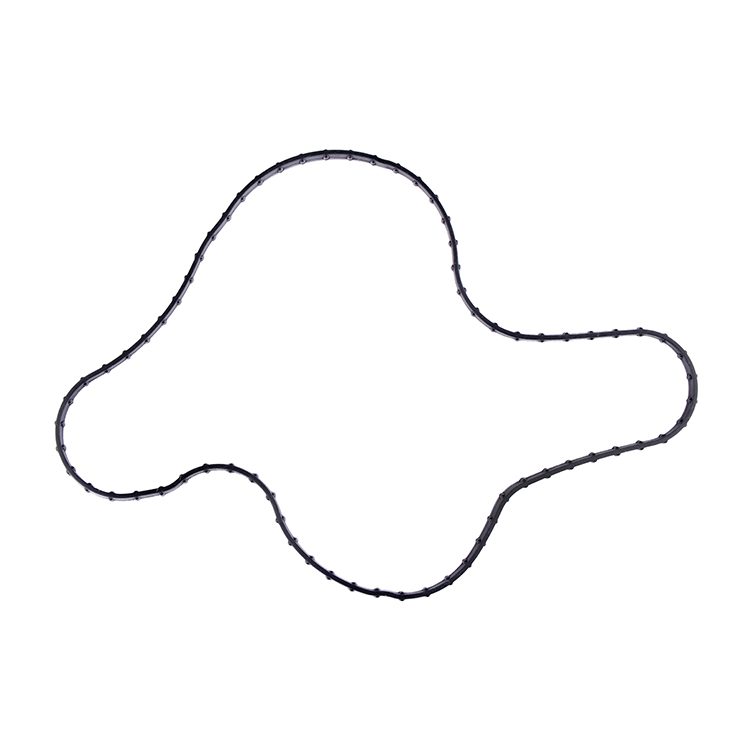

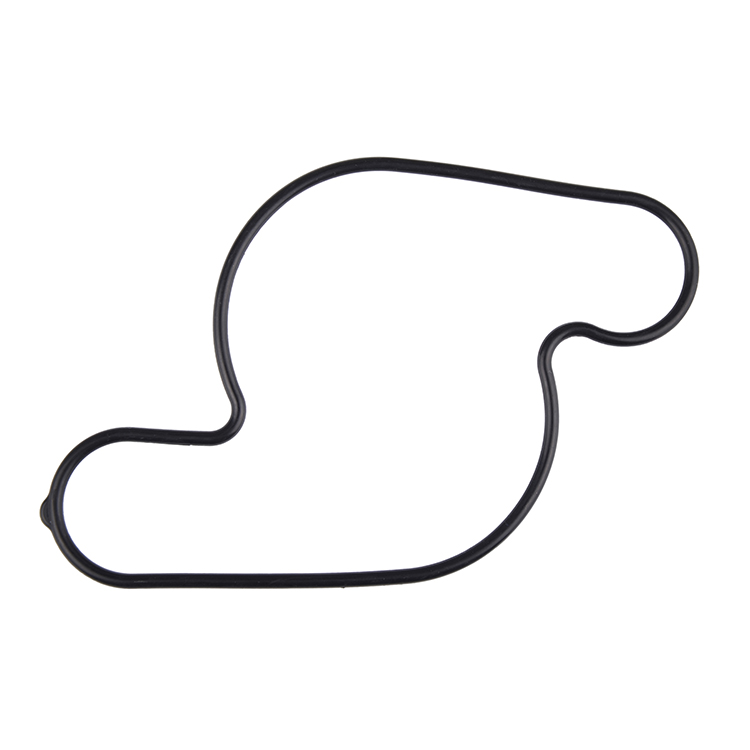

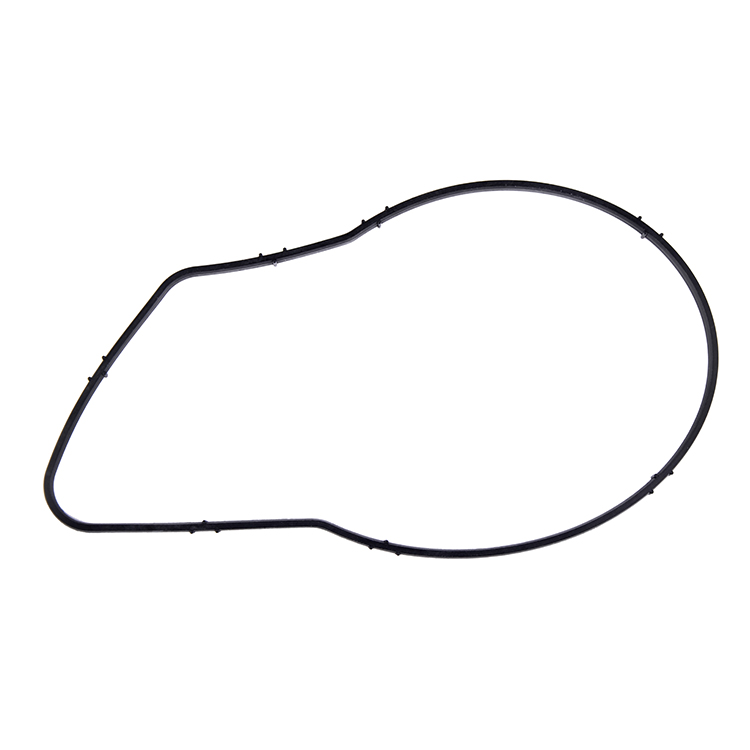

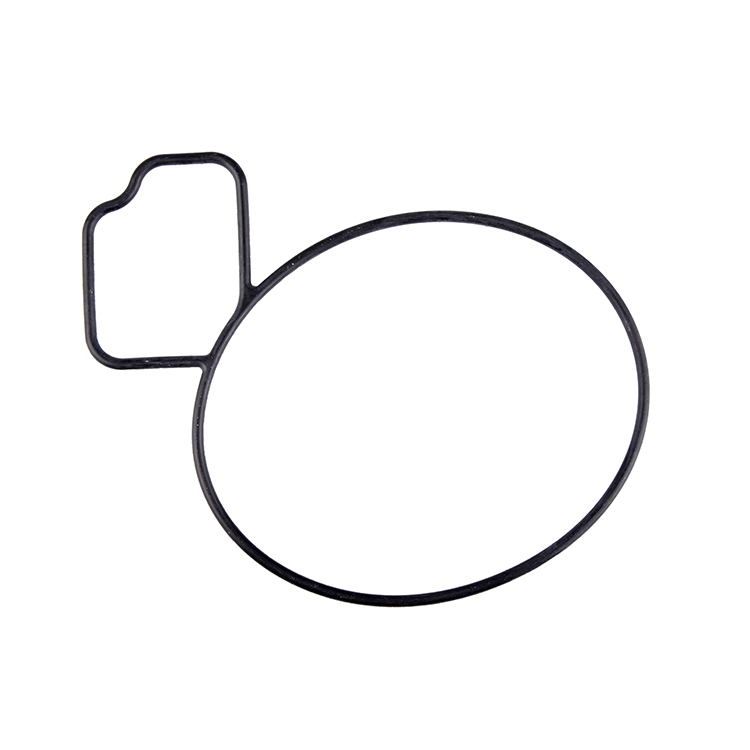

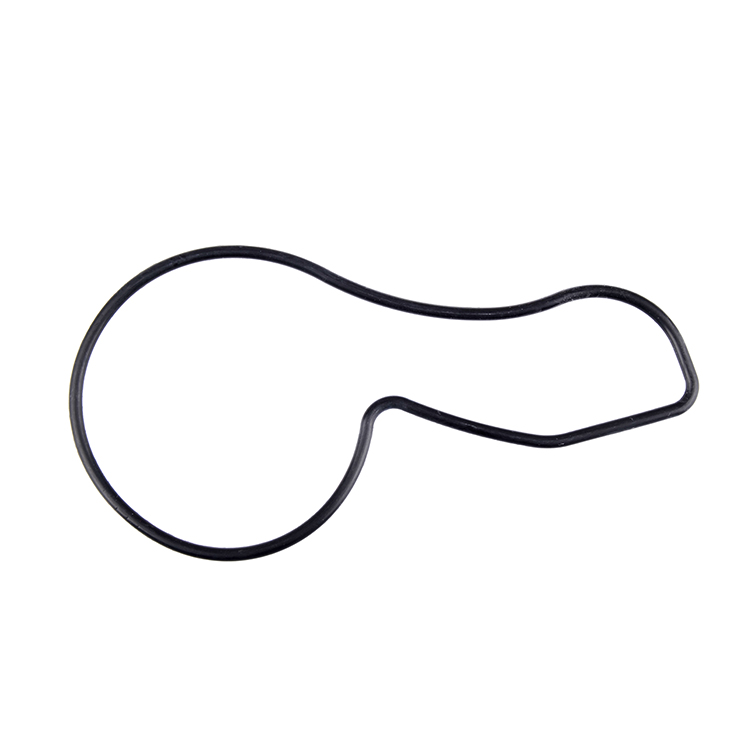

Conductive electric silicone rubber seal

Port:xiamenPayment Terms:L/C,D/P,T/T,Western Union,MoneyGramSupply Ability:50000000 Piece/Pieces per MonthPlace of Origin:Fujian ChinaBrand Name:Best SealModel Number:BSC145378Standard or Nonstandard:NonstandardMaterial:rubberSize:custom sizecompound material:meet ASTM D2000, ROSH complianceColor:Any pantone color availableQuality:Can be ROSH, REACH, FDA, NSF , DVGW complianceApprearance:Free of knit, void, lack of material , tool marking&any imperfedTolarance:DIN ISO 3302-1 M2, RMA A2 or as per customer designPackaging Detail:Inner: polybag

Outer: export grade carton

Finally, put on pallet

| Production information | |

| Description | rubber seal electric |

| Material | EPDM, NBR, SBR, CR, FKM, PU, SILICONE, HNBR, AEM, ACM, XNBR,NR, IIR, PTFE and so on |

| Compound material | Meet ASTM D2000 and can be UL, FDA, ROSH, REACH approved |

| Hardness | From 20 ~ 90 shore A |

| Color | As per request |

| Size | custom size |

| Property | a.Ozone and chemical resistance b. High temperature resistance c. Excellent weather resistance d. Anti-aging, anti-radiation, good flexibility, good elasticity e. Excellent resistance of acids, aliphatic hydrocarbons, aromatic hydrocarbons and animal and vegetable oil |

| Package | PE bag, Carton |

| Leadtime | 8 days for sample, 12~18 days for mass product |

| Other | we have molds for all AS568 size |

| Brand raw material used | |

| NBR: | KUMMO, NANTEX, LANXESS, ZEON |

| EPDM: | KUMMO, LANXESS |

| SBR: | LANHUA |

| CR: | FUJI Electric |

| FKM: | CHENGGUANG, DUPONT |

| PU: | LANXESS |

| SILICONE: | Shin-Etsu, Dow Corning, Dong-Jue |

| HNBR | ZEON, LANXESS |

| AEM: | FUJI Electric |

| ACM: | ZEON |

| Production capacity | |

| Mode of production | Compression molding, Transfer molding, Injection molding or Extrusion |

| Surface treatment | Talc, silicone grease, teflon, graphite coating or ground surface |

Best Seal is a professional manufacturer and seller for standard & ready source for non-standard seals & make-to-print rubber parts. Exporter of rubber O-rings/ hose/gasket/ grommet/ seal/ ball, etc,. Technical & application assistance is available. Our technical teams we have served the sealing needs of thousands of OEM and aftermarket users. From Auto parts, micro pump, sanitary, medical, electric, to parts on the space shuttle for more than 20 years. we have designed, manufactured and supplied a wide variety of rubber, plastic and metal items.

1)We have ready mold for all AS568 o-ring.

2)one stop service including rubber part,plastic part, extrusion part,sponge part,spliced part.

3) Our senior engineer has been doing and researching on rubber product for about 20 years.

4)Our quality control 100% follow up ISO9001:2008.

5) We mix compound material 100% as per ASTM D2000 or customer’s specific.

Q 1. What’s the payment term?

A: We accept T/T 50% deposit and 50% balance before delivery or L/C at sight, Western Union,Paypal is also accepted.

Q 2. What is the normal lead time for product orders?

A: Average lead times for prototype / first article are around 2 weeks, if tooling is involved, lead time for production tooling is around 10 days, average production time after sample approval is 2-3 weeks.

Q 3. What is your standard packing?

A: All the goods will be packed by PP bag and then carton box. Special packing method can be accepted when needed.

Q 4. Could you please tell us the month capacity of your products ?

A: It depends on which model, we produce more than 2000 tons rubber materials per month.

Q 5. what kind of certificates you have ?

A1: We have been ISO9001:2015.

A2: We have various rubber compounds approved by UL, FDA, NSF, KTW, W270, WRAS, ACS, AS4020, EN681, EN549, ROHS and REACH.

Q6: How to check the quality of the bulk order?

A1: We provide pre-production samples before mass production for all customers if needed.

A2: We provide quality certs such as measurement report, material data sheet to all customers before delivery.

A3: We accept third party inspection such as SGS, TUV, INTERTEK, BV, etc.

Q 7: How to select the raw compound for my application?

A: With years of experience working with a variety of material, we can help select the material that will best suit your needs while keeping material costs in mind.

Q 8: Do you use any international standards for the rubber products?

A: Yes, we mainly use ASTM D2000 standard to define the quality of the rubber materials, tolerances as per ISO3302, RMA, etc.

Q 9:Can you supply different color materials?

A: Yes, we can produce custom molded rubber and silicone rubber products in different colors, the color code will be required in case of an order.

Q10: What materials are available to produce from your side?

A: NBR, EPDM, SILICONE, FKM, NEOPRENE(CR), NR, IIR, SBR, ACM, AEM, Fluorosilicone(FVMQ), FFKM, Liquid Silicone, Sponge, etc.

Q 11: What is the life expectancy of the rubber seal?

A: Product life is contingent upon many factors, including environment, cycles, pressure, etc. Best Seal cannot predict seal life under all the varying conditions of operation. Accellerated life testing may be performed by customer to determine expected life, but must be conducted in dynamic application.

Q12: Does Best Seal provide maintenance on tooling?

A: Best Seal maintains all tooling and will replace as needed.

Conductive electric

silicone

rubber seal

Reviews

There are no reviews yet.