Products

- Home

- Rubber Gasket

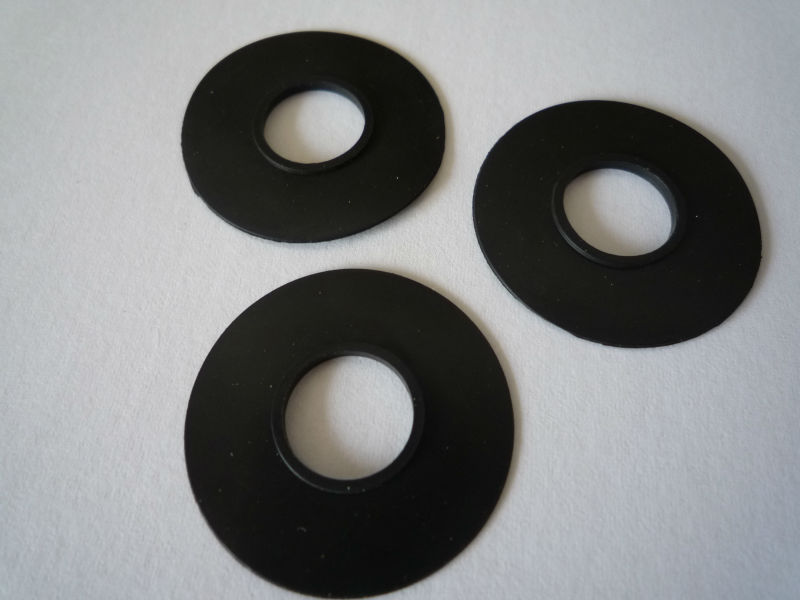

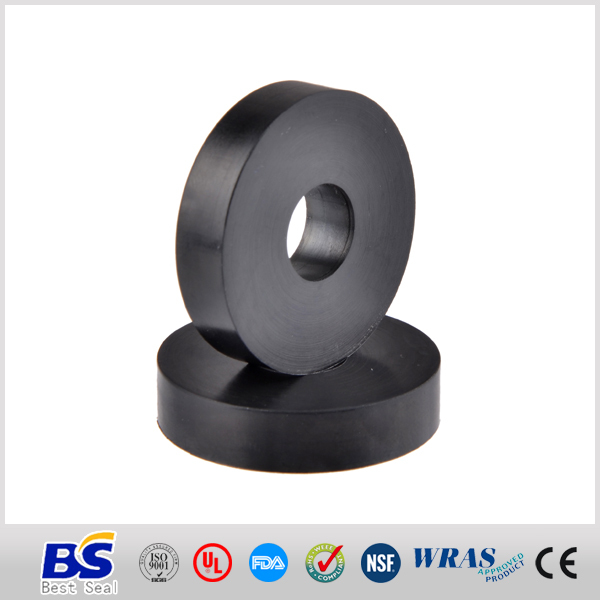

- Stainless Steel EPDM Rubber Washers

Stainless Steel EPDM Rubber Washers

Place of Origin:Fujian ChinaBrand Name:KSO-129HModel Number:BestSealMaterial:RubberStyle:O RingSize:as per custom/OEMStyle:machine sealHardness:20-90ATolerance:DIN ISO 3320-1,M2,RMA A2 or as per custom needAppearance:no tooling mark, no burr, no void and other imperfectQuality:Meet ASTM D 2000, ROSH ,NSF, UL ,FDAStandard size:AS568,DIN3371,JIS B2401, BSColor:as per custom needPackage:PE+ CartonDelivery:8days for sample, 12-18days for mass productsStandard or Nonstandard:NonstandardDelivery Detail:15 days after paymentSelling Units:Single itemSingle package size:20X30X40 cmSingle gross weight:1 KGPackage Type:PE+ Carton

| Production information | |

| Description | gasket for aluminium window |

| Material | EPDM, NBR, SBR, CR, FKM, PU, SILICONE, HNBR, AEM, ACM, XNBR,NR, IIR, PTFE and so on |

| Compound material | Meet ASTM D2000 and can be UL, FDA, ROSH, REA o rings silicone CH approved |

| Hardness | From 20 ~ 90 shore A |

| Color | As per request |

| Size | AS568, JIS B2401, DIN 3371 or custom size |

| Other | we have molds for all AS568 size |

| Brand raw material used | |

| NBR: | KUMMO, NANTEX, LANXESS, ZEON |

| EPDM: | KUMMO, LANXESS |

| SBR: | LANHUA |

| CR: | FUJI Electric |

| FKM: | CHENGGUANG, DUPONT |

| PU: | LANXESS |

| SILICONE: | Shin-Etsu, Dow Corning, Dong-Jue |

| HNBR | ZEON, LANXESS |

| AEM: | FUJI Electric |

| ACM: | ZEON |

| Production capacity | |

| Mode of production | Compression molding, Transfer molding, Injection molding or Extrusion |

| Surface treatment | Talc, silicone grease, teflon, graphite coating or ground surface |

| Package | PE bag, Carton |

| Leadtime | 8 days for sample, 12~18 days for mass product |

Why Choose Us?

We offer:Industry-Leading Quality,Meet ROSH, FDA, Reach, NSF

- On-Time Delivery (across town, or around the globe)

- Product Liability Insurance

- Personalized Service with Rapid Response Times

- Custom Solutions for your Custom Needs

- Competitive Pricing

(1)Q: Do you offer samples of rubber product?

A: We are glad to offer you free samples. New clients are expected to pay for the delivery cost,this charge will be deducted from the payment for formal order.

(2)Q: How about the lead time?

A: Within10-20 days after getting the prepayment.

(3)Q: How can we pay?

A: For small sample shipping cost, you can pay either by paypal or by T/T.

About us

Best Seals does more than just supply standard parts, a large percentage of our business is based on custom product. We sell custom parts to original equipment manufactures (OEM’s), and to smaller distributors who have custom products they need sourced. Custom produced product allows for more complex designs that can tackle problems that standard parts fail to properly solve. Some of the highlights of our custom products division are:

•Custom products that are manufactured to your specifications.

•Best Seals can supply custom parts in virtually any material.

•Professional engineerer team help with the material selection process.

•Custom materials to meet specific color, fluid resistances, or physical properties.

•Prototyping of experimental designs.

Reviews

There are no reviews yet.