Technical Teams

Quality Control

Our technical teams we have served the sealing needs of thousands of OEM and aftermarket users.

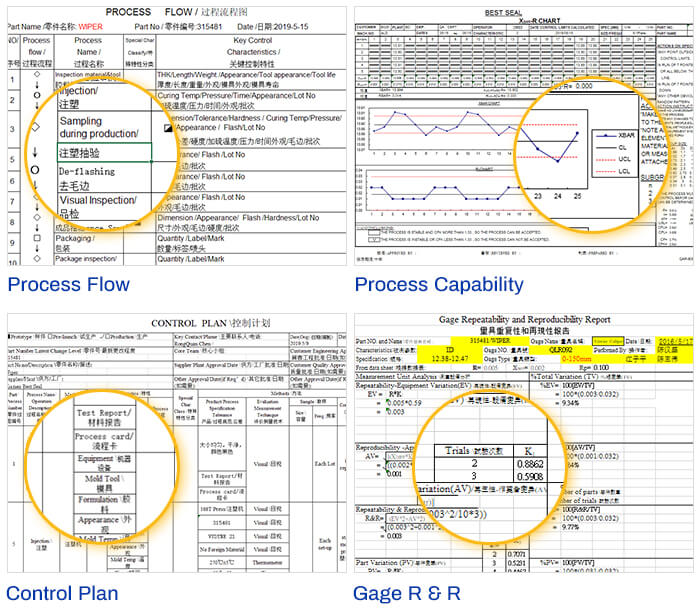

Sampling

During

Manufacturing

01

We have ready mold for all AS568 O-ring.

We mix compound material 100% AS PER ASTM D2000 or customer's specific.

Quality

Checking

Before

Deflashing

02

Make semi-product from teflon powder. That allow us to control quality from raw material and reduce cost.

100%

Inspection

03

Precise lathe finish product to make sure high precise dimension.

We have ready mold for all AS568, DIN JIS and metric standard size.

We are available from tiny(ID0.8 x CS0.2mm) to big (ID1000) size.

Quality

Assurance

as Per

AQL Level

04

We have auto machine to do 100% checking on o-ring.

We have ready mold for all AS568, DIN JIS and metric standard size.

Our quality control 100% follow up ISO9001:2008.

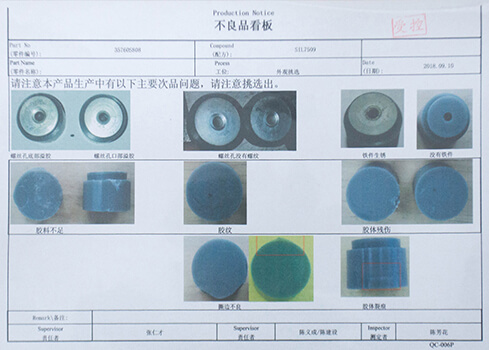

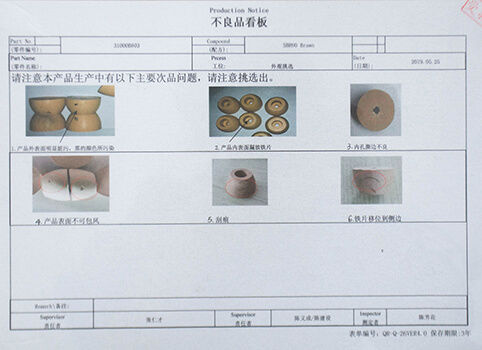

Final

Inspection

Before

Shipment

05

Precise lathe finish product to make sure high precise dimension.

We have ready mold for all AS568, DIN JIS and metric standard size.

We are available from tiny(ID0.8 x CS0.2mm) to big (ID1000) size.

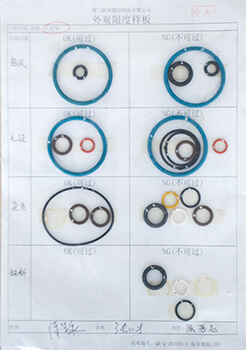

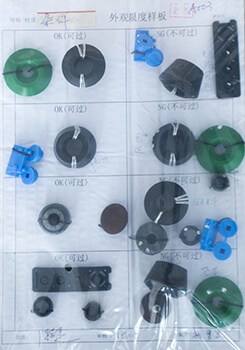

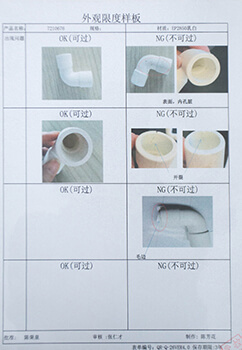

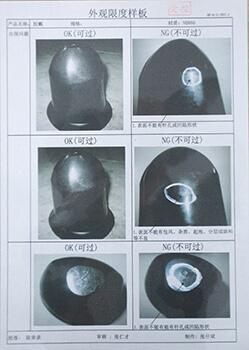

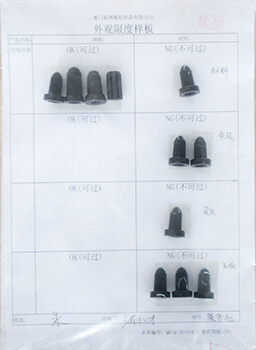

Outside viewing board

Services

One-stop solution

to your sealing

application.

We provide a one-stop-service to your sealing solutions.Tell us what you want to seal, let us assist with your current production or design requirements

Engineering

Assistance

Best Seal technician team spent more than 10 years helping our customer optimize the seal engineering.

Our Consultation includes:

• Material optimization

• Part integration

• Accounting for dynamic vs static conditions.

• Proper part tolerance and interface design

• Quality checking before shipment

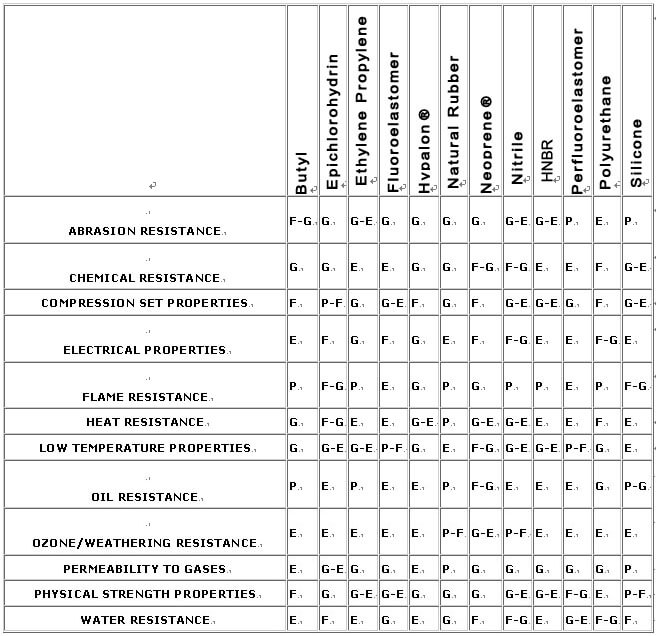

Material

Compatibility

BASIC PROPERTIES - ELASTOMERS

Key: E = Excellent G = Good F = Fair P = Poor The information given above is only an indication of the properties achievable for the range of elastomers listed. Best Seals offers no guarantees on the suitability of its products for a particular set of conditions based upon the contents of this table.

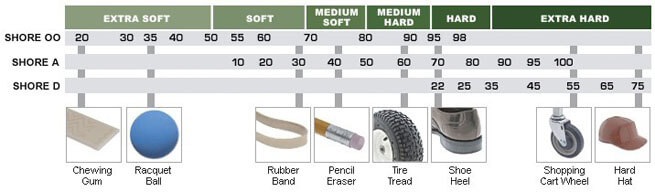

Durometer

Durometer is the international standard for measuring the hardness of rubber, plastic, and most nonmetallic materials. The hardness of a material is its resistance to surface penetration. Harder materials have more wear resistance, but they are also less flexible. Note that an object may fall within more than one scale. For example, a typical shoe heel is 95 Shore OO, 70 Shore A, and 22 Shore D durometer.

Equivalent

Materials

Once a factory has implemented Lean Principles and optimized their cost structure, they need optimize their part design to reduce costs. Equivalent Materials is the first place to look for cost reduction initiatives. Best Seal’ extensive application experience can assist the customer in choosing the optimal material.

Certifications

Qualification and Approvals are the backbone of ensuring product performance and limiting product liability. Best seal’ vast factory network allows us access to a wide variety of compounds and approvals. This ensures that the factory focuses on their core competency and we provide one stop shopping. This is yet another way that Best seal simplifies your procurement and optimizes your engineering.

PPAP

Approvals

PPAP

Automotive customers typically require extensive product validation. An essential part of the validation process is proving that a part has a capable and repeatable process. A high Cpkensures that quality is part of the process and that a vendor is not relying on final inspection to ensure product quality. Best seal’ Black technician team have the requisite knowledge to ensure that a capable and repeatable production process is the first line in our quality defense.